The new, old lathe arrived yesterday. The Unimat 4 is manufactured in the far east, and you can certainly tell the difference. A proper Unimat it aint.

I carefully checked it over last night and it is in good condition for what it is, and will make a good lathe in the end ..... but .... there were a number of problems.

I stripped the entire machine down, and the beds and ways are in good condition with no knocks or scrapes. There are signs of hand lapping or scraping and the ways are well finished. There was swarf and shit everywhere and signs of the original packing grease. This was all removed. It took ages to get all the crud out of the leadscrew though.

The machining of some of the parts is passable at best and not good at worse. What was indescribably stupid were the aftermarket products. A quick change toolpost (QCTP) and a taper-turning top slide. The toolpost had been fitted upside down with a huge washer on the top. At first I couldn't fathom out why, but it then became obvious. The securing bolt that fits the clamp nut was at least 5mm too long for this model. Instead of cutting it back down (as I have now done) the previous owner had driven it into the bed of the cross slide which had deformed it! He had then flipped it over and added the washer to take up the difference. I have checked and this is the bolt supplied with the part. Stupid of the manufacturers.

The taper-turning slide had similar problems. The locating shoulder was about a millimeter to long to fit the hole and the securing bolt was also about 3mm too long. Again I think the previous owner had tried to force it to fit, which is sort of understandable if the product is sold as ready for the machine. I had to grind the shoulder down so that it was a drop in fit and reduce the length of the securing bolt.

Both aftermarket products now fit correctly and the QCTP is really nicely made and will come in very useful.

The deformed part of the cross slide was riding on the un-machined part of the saddle. Useless for any kind of meaningful work. Eventually I will hunt down a replacement, but for now I had to grind back a relief which has left a small hole in the base of the slide. Luckily not anywhere that matters but it may left swarf into the thread. Damn.

All the gibs had to be reset, mostly I fear due to the damage to the slide, but it now runs cleanly and all the threads are clear. The tailstock appears to be fine, so i just gave it a clean up. The keyless chuck as supplied is useless really, it's so long that it reduces the between centre size to about 5 inches. These machines were originally supplied with a 10mm Jacobs chuck, which is missing.

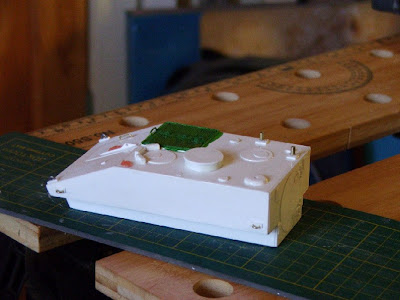

Here's the lathe as it arrived:

Now to the more serious shortcomings of the machine. The motor mount is bloody awful! On the old SL/DB it was a rough, but sturdy alloy casting machined for the location points. This model has a piece of 3mm pressed steel to carry the motor and the idler and it bolts to the back of the headstock. It flexes like crazy. there's a point between the headstock and the motor where you can flex the mounting plate. You can move the back of the motor by 3 or 4mm. Not good.

On a first test cut it was obvious that there are runout problems. About 20thou at 2 inches from the chuck. I have ordered a dial gauge to find out if it's the chuck (hopefully) or a problem with the headstock. I am beginning to wonder if a tool was driven into the original Jacobs chuck and that's why it's missing.

If it's the headstock, then I either have to fit new bearings (a daunting task) or find another headstock. If it's the chuck then getting another won't be a problem.

It could be that the thread of the chuck is as bad as all the other bits so I've ordered a tap so I can run it through.

If I had access to bigger machinery I would try to machine a new motor mounting plate from quality alloy. Anyway I had to adjust all the pulleys since they didn't line up and I've ordered a new set of belts too.

Why go to all this trouble? Well the machine was CHEAP even for this model and it has much better bed clearance than the SL. Even with riser blocks.

If I spend another £100.00 getting it all working then it will still be cheaper than a second SL or a Mk3.